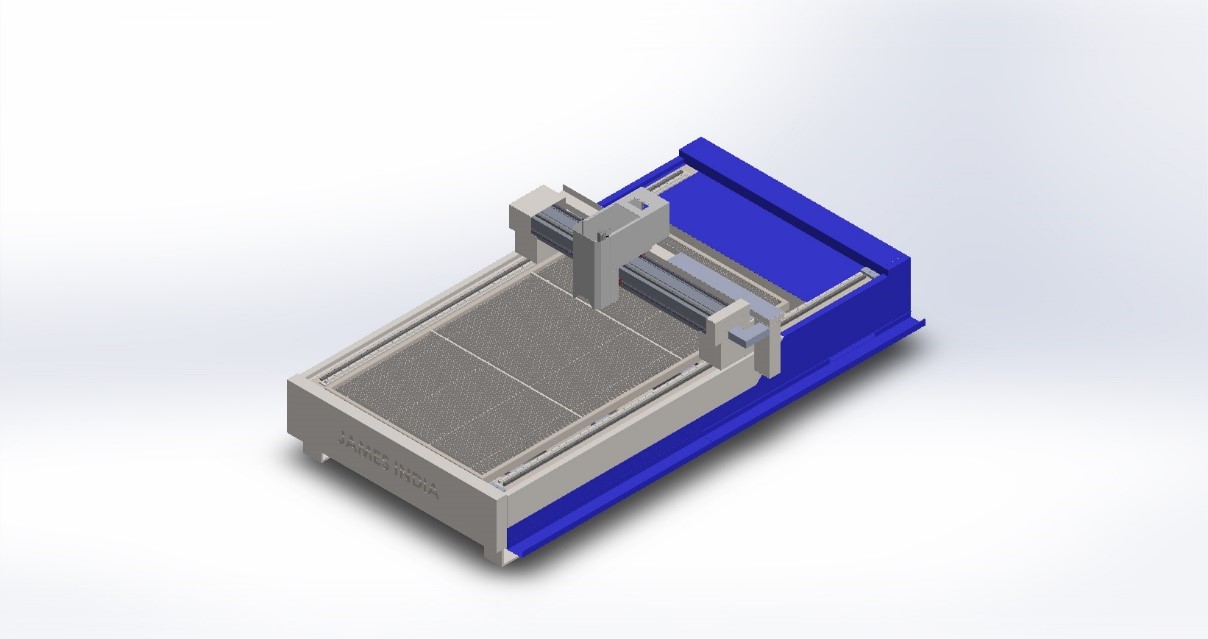

JAS series is a perfect standard plane fiber laser cutting machine, which is popular in the industry. It has the highest speed among those with the same level and may cut 400 small circles per minute. With the maximum speed of 140m and maximum acceleration of 1.5G, it has the highest accuracy among those with the same level and may cut the bicycle with the size of 1/5 of coin.

Pioneered simple and integrated integration design all over the world.

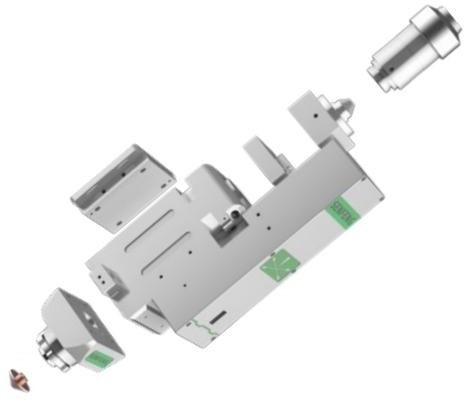

The cast-aluminum beam is cast and molded with 10t of steel mold for the first time in the industry, with good rigidity and high strength, whose weight is 1/2 of that of the traditional welded iron beam.

| Name | Quantity | Brand | Brand Of Country |

|---|---|---|---|

| 1000W Laser | 1 Set | Max/IPG | Max/IPG |

| Special Precision Cutting Head For Fiber | 1 Set | Roy tools | Switzerland |

| Precise Rack | 3 Set | YYC | Taiwan |

| Reducer (Including Gears) | 3 Set | YYC | Japan |

| High Speed Servo Motor And Drive | 4 Set | PANASONIC | Japan |

| High Precision Linear Guild Rail (Tool) | 3 Set | HIWIN | Taiwan |

| Precision Ball Screw (Z-axis) | 1 Set | HIWIN | Taiwan |

| Numerical Control System | 1 Set | FScut | China |

| Electric Control | 1 Set | Schneider | France |

| Gas Circuit Control | 1 Set | SMC | Japan |

| Mechanical Platform And Accessories Of Tool | 1 Set | JAMES | India |

| Water Chilling Unit | 1 Set | S & A | China |

| No. | Type | RAS-3015 | |

|---|---|---|---|

| 1 | Max Cutting Size (mm) | 1500x3000 | |

| 2 | Max Height of The Workpiece (mm) | 90 | |

| 3 | Effective Travel | X Axis (mm) | 1505 |

| Y Axis (mm) | 3005 | ||

| Z Axis (mm) | 150 | ||

| 4 | Positional Accuracy | X Axis (mm) | ±0.04 |

| Y Axis (mm) | ±0.04 | ||

| Z Axis (mm) | ±0.01 | ||

| 5 | Repeated Positioning Accuracy | X Axis (mm) | ±0.03 |

| Y Axis (mm) | ±0.03 | ||

| Z Axis (mm) | ±0.005 | ||

| 6 | Re-positioning Speed | X Axis (m/min) | 110 |

| Y Axis (m/min) | 110 | ||

| Z Axis (m/min) | 110 | ||

| 7 | Accelerated Speed (G) | 1.5 | |

| 8 | The Laser Power(W) | 1000 | |

| 9 | Level of Protection | IP54 | |

| 10 | Boundary Dimension L×W×H(mm) | 4600X3200X1800 | |

| 1000W(50µm) | ||

|---|---|---|

| Mild Steel | 12 | 10 |

| Stainless Steel | 6 | 5 |

| Aluminum | 3 | 2 |

| Brass | 3 | 2 |

Gantry machine body, designed and manufactured for the high-speed movement. Twice of aging treatment of reinforcement welding machine body to ensure the precision and stability of the long running. The rigidity is good, the higher acceleration can be accepted, the main body adopts the precise welding of steel structure, the stress failure treatment, the gantry milling of the heavy frame structure.

The main body frame is welded with the carbon dioxide protection welding, with such advantages as stable welding process, free internal defect, minimum splash, etc. At present, such welding becomes the most important welding for the black metal material.

The material stress resulting from welding is eliminated. A very large fuel heating annealing furnace is used to perform stress annealing for several body frames at 600℃ at the same time. With stable furnace temperature and uniform electronic monitoring, the welding stress is thoroughly removed, with guaranteed quality.

Annealing of one small non-common electric furnace with non-uniform temperature cannot guarantee to thoroughly eliminate the stress

The heavy-duty steel mold pressure casting is used.

HIWIN is a Taiwanese company responsible for the production and development of linear guide.

Adjust and create blueprint display

Optimize graphics

Shunt

Rapid cutting

Define the starting and ending points

Automatic layout drawing

Optimized and diposed complex contours and angles

Set the cuts and tangents

utomatic setting of speed and cutting power

The cutting head moves with the plate

Instantaneous detection and evaluation system security